Cellular polycarbonate has become one of the most popular transparent materials for covering greenhouses in summer cottages. It gives the structure a beautiful appearance, transmits sunlight and has excellent thermal insulation, and you can fix it yourself on the roof and walls of the greenhouse even in the absence of special skills.

The article describes the main types of fastening devices for fixing the casing on the metal frame of the greenhouse, lists the types of connecting profiles, and also provides recommendations on how to properly fix this material and what tools are needed for this.

What tools will be required?

Before you begin attaching cellular polycarbonate to the frame of the structure, you need to cut the sheets in accordance with the dimensions of the greenhouse. To fix the material on the surface of the structure, use various types of fasteners.

And for cutting panels and lining the metal frame of a greenhouse, you will need such tools:

- jigsaw (or sharp knife, band saw) - for cutting sheets into individual parts;

- Roulette - with its help, the length and width of each fragment are measured;

- electric drill and drill for metal - for making holes in the frame of the structure;

- self-tapping screws, washers and bolts with nuts - press the skin to the surface of the frame;

- construction level - needed to level the surface of the coating;

- ladder - for covering the roof of the structure with polycarbonate;

- screwdriver - for fast twisting of fasteners;

- manual hacksaw for metal - used to separate the connecting profiles into segments of the desired length;

- vacuum cleaner - to collect dust and small parts after completion of work.

Did you know? Most greenhouses are located in the Netherlands - the total area of closed greenhouses in this country is about 10,500 ha.

Fasteners

In order to attach polycarbonate to a metal frame, self-tapping screws and various types of sealing washers are used. They help to securely fix the material on the frame, and you can purchase them in specialized stores. Washers look beautiful on the surface of the greenhouse and protect it from excessive deformation. In addition, they prevent the penetration of moisture and dust into the material in the place where it is pierced by a self-tapping screw. We will describe in more detail about the better fixation of the casing on the metal framework of the greenhouse.

Washers look beautiful on the surface of the greenhouse and protect it from excessive deformation. In addition, they prevent the penetration of moisture and dust into the material in the place where it is pierced by a self-tapping screw. We will describe in more detail about the better fixation of the casing on the metal framework of the greenhouse.

Polycarbonate Thermowells

This type of fastener is made of transparent polycarbonate and can be produced in various colors. The thermal washer fits tightly into the hole made and expands during thermal loading, preventing deformation of the greenhouse coating.

Important! Polycarbonate thermal washers are universal mounting materials and can be used for cladding a greenhouse with either a metal or wooden frame.

The main characteristics of this type of washers:

- The main component of the fasteners is a volume washer with a hole for a self-tapping screw in the center and a wide leg, the length of which is equal to the thickness of the polycarbonate sheet.

- In addition to the washer, the kit includes a sealing ring made of foamed polyurethane and a plastic plug that is worn on top. A self-tapping screw for fixing the washer is purchased separately.

- The diameter of the fastener is 33 mm, and its thickness is 8 mm.

- The service life of such a thermal washer is about 20 years. Fasteners are selected individually depending on the thickness of the sheets of the sheathing material.

- A polycarbonate thermal washer helps to achieve a snug fit of the greenhouse sheathing to the frame and gives the exterior surface of the building a decorative look.

Polypropylene washers

This type of fastener has a lower cost compared to thermal washers and is also available in various colors, but differs in a short service life. In addition, it is necessary to screw the polycarbonate to the frame using polypropylene washers - they do not have a limiting leg, so there is a risk of stretching the greenhouse cover too much and deforming the sheets.

Characteristics of polypropylene washers:

- The key element of the washer is a polymer cover, in the center of which there is a hole for a self-tapping screw. Complete with it is a sealing ring made of polyurethane foam and a cap.

- It has a relatively large size - the diameter is 35 mm, and the thickness is 12 mm.

- For fastening such washers, 6 mm thick screws must be used.

- The plugs do not have a layer of protective coating from ultraviolet radiation, so they quickly fade in the sun and begin to collapse.

- Average life - no more than 4 years.

- Universal and can be used for fastening polycarbonate sheets of any thickness.

To extend the service life of polypropylene washers, it is recommended to use them only indoors or for cladding structures located in partial shade.

Stainless washers

This type of fastener is mainly used for cladding large structures. Washers made of stainless material are durable and reliably fix polycarbonate on a metal frame even in strong winds.

Characteristics:

- The kit includes a round metal plate in the form of a plate with a hole for a self-tapping screw in the center, as well as an umbrella pad made of EMDP rubber, flexible plastic or foamed polyurethane.

- The diameter of the fastener is 22 mm, and the thickness is only 2 mm.

- Can be used to fasten panels of any thickness.

- The material of the umbrella pad remains flexible even at an air temperature of –15 ° С. It tightly presses the polycarbonate sheet to the frame, preventing moisture from entering the skin cells and does not become loose over time.

- This type of fastener does not have a plug that closes the cap of the fastener on the outside, so the screws and bolts used to cover the greenhouse, in this case, must be made of corrosion-resistant materials.

Connection profile selection

When covering the greenhouse with polycarbonate, in addition to the washers, special connecting profiles are also used. They are designed for tight connection of sheets of material at the joints and can be made of polycarbonate, plastic or aluminum.

Important! Manufacturers offer different connecting profiles for polycarbonate with a thickness of 4, 6, 8, 10, 16, 20 and 25 mm. The edges of the sheet are fixed inside them using self-tapping screws and washers.

Types of profiles for attaching polycarbonate to the greenhouse:

- UP-end - designed to protect the polycarbonate edge from moisture and dust. The profile has a standard length of 2.01 m and there are varieties on sale for sheets of any thickness.

- K-ridge - with its help joints of material on two roof slopes are connected, provided that the angle between them is more than 90 °. The standard profile length is 6 m, and it can be used for sheets with a thickness of up to 16 mm.

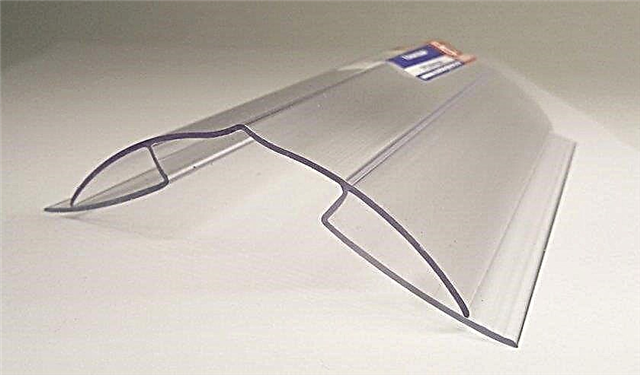

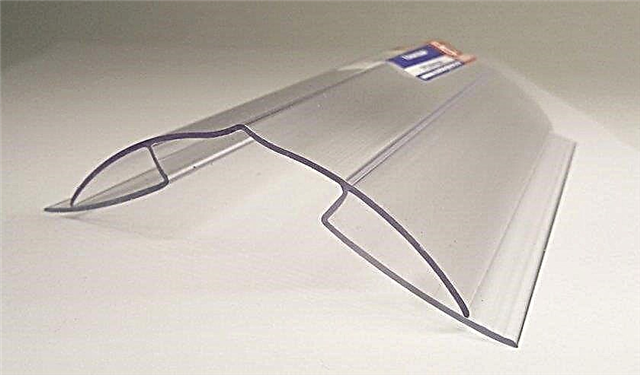

- Detachable NDS Profile - designed to connect adjacent polycarbonate panels and consists of a base and a removable cover. The base is attached to the frame of the greenhouse with self-tapping screws, and the edges of adjacent sheets are laid on it and fixed on top with a lid. The standard profile length is 6 m, with its help it is possible to fix panels up to 16 mm thick.

- One-piece HP docking - is a monolithic H-shaped part having special grooves on both sides for inserting the ends of adjacent sheathing sheets. The profile length is 6 m, and it can be used to connect panels up to 10 mm thick.

- Y-angular perpendicular - helps to join polycarbonate sheets at an angle of 90 ° and is used to fix the casing at the corners of the greenhouse. The standard profile length is 6 m, it is designed for panels up to 10 mm thick.

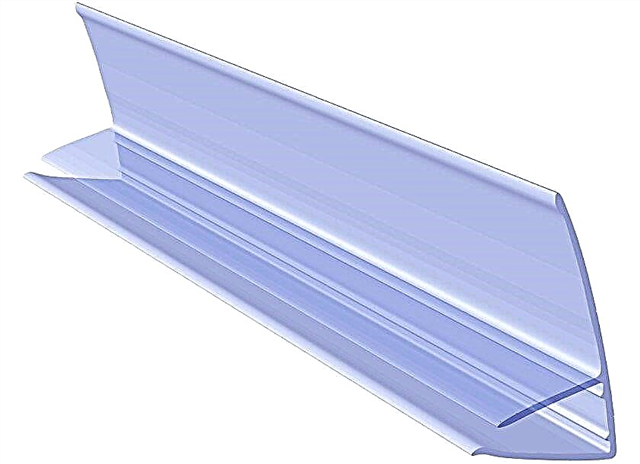

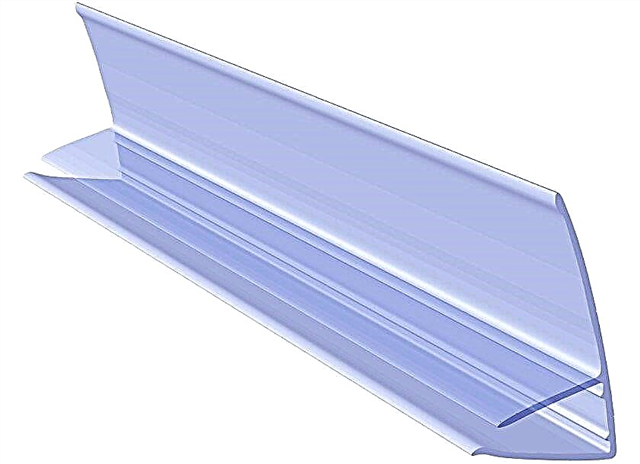

- F-wall - It is used in order to fit the polycarbonate sheet tightly to the wall and has a length of 6 m. Manufacturers produce various options for panels with a thickness of 4 to 10 mm.

Rules for attaching polycarbonate to the frame

In order for the heat to be well preserved inside the structure, and the polycarbonate not to deform under the influence of wind and temperature changes, you need to know how to properly fix the casing.

In this case, the panels should be placed so that the side with the protective coating is outside the greenhouse, and all the joints are strictly on the metal strips of the frame.

Tighten the screws and washers must be strictly at right angles to the surface of the frame. At the same time, fasteners should not over-press the casing.

Important! Before driving the edges of the polycarbonate sheets into the profile, they must be glued with a perforated or sealing tape - this prevents moisture and dirt from getting into the material.

Step-by-step instructions for covering the greenhouse with polycarbonate:

- Lay a layer of heat-insulating tape on the surface of the metal frame.

- Cut the material into separate parts according to the size of the greenhouse, spreading the material on a flat surface. On each part, outline the places in which the skin will be attached to the frame.

- Drill holes in the designated polycarbonate places, observing a distance of 40-60 cm between them. The diameter of the holes made should be 2-3 mm larger than the thickness of the self-tapping screw or the leg of the thermowasher that are used for fastening.

- Attach the cut material parts to the frame of the greenhouse. Using a thin drill for metal, drill holes for self-tapping screws in metal strips so that they coincide with the holes on the sheet.

- Lay the skin panels to the side and attach the connecting profiles with the screws in the right places on the greenhouse frame. The most convenient are detachable profiles, allowing effortlessly fitting the joints of adjacent panels to each other.

- Attach polycarbonate to the connecting profiles and the frame so that the edges of the panels fall into the corresponding grooves. The recommended clearance is 2.5 cm.

- Fix the casing in the greenhouse using self-tapping screws and washers inserted into the prepared holes on the polycarbonate panel. Insert the plugs in the washers, and then attach the upper parts of the profiles, firmly fixing the panels on the frame of the structure.

- Remove the outer protective film from the skin surface. Remove construction waste.

Video: Installation and mounting of polycarbonate in the greenhouse

It is not so difficult to independently sheathe the metal frame of the greenhouse with polycarbonate sheets. To understand how best to fix the coating, you need to use the above information about the types of fasteners and clearly adhere to the recommendations listed above for installing panels on the metal strips of the greenhouse.